Convenient

Get it at your preferred time and place

Reliable

You’d get good quality wheelie from us

Active

Just be active & alive

Blogs

Why We Travel With Our Bikes: A MTB Adventure from..

Why checking your Bottom Bracket Matters: Don't Lo..

After Wheel Truing the Dented Rim, Why Is It Still..

How to Do Drill Slalom with Cones at the Park

How to stand on the slope with your mountain bike?

Why We Travel With Our Bikes

Why it is important to put back the right bolts du..

How to Build a Wheelset for Your Bicycle

How to do basic cornering with junior mountain bik..

How to Build a Wheelset for Your Bicycle

Building your own wheelset is one of the most rewarding skills in cycling. It’s part precision, part patience, and 100% satisfaction when you roll away on a wheel you built with your own hands.

Here’s a simple, step-by-step guide based on our latest workshop video:

1: Prep the Spokes and Nipples

Start clean. Before anything else, prepare your spokes and nipples

-Apply a small dab of grease to each nipple

-Apply a small dab of anti seize to the spoke threads

-this prevents corrosion and makes future truing easier

2: Screw on the Nipples

Next, begin threading each nipple onto its spoke by hand. This ensures smooth rotation and avoids cross-threading. You'll tighten them more later during the truing process.

3: Lace the Wheel

Now comes the most technical part-- lacing

Follow your chosen pattern (most use a 3-cross pattern for strength)

-Start with the inner spokes from the hub flange.

-Then insert the outer spokes. weaving them over and under.

-Keep your lacing symmetrical on both sides of the wheel.

Take your time here, proper lacing sets the foundation for a true and durable wheel.

4: Tighten the Nipples

With all spokes laced, begin tightening each nipple gradually and evenly. Don't rush, tighten a few turns at a time in a cross-pattern to keep the rim balanced.

5: Distress the Spokes

once tension builds up, distress the spokes by gently flexing the spokes.

This helps settle everything and reduces future spoke loosening.

6: True and Tighten again

Now its time for truing, the art of making your wheel perfectly straight and round.

-Use a truing stand

-Adjust spoke tension gradually to eliminate wobbles and hops

-Recheck roundness and dish every few turns.

When done correctly, your wheel should spin smooth and silent.

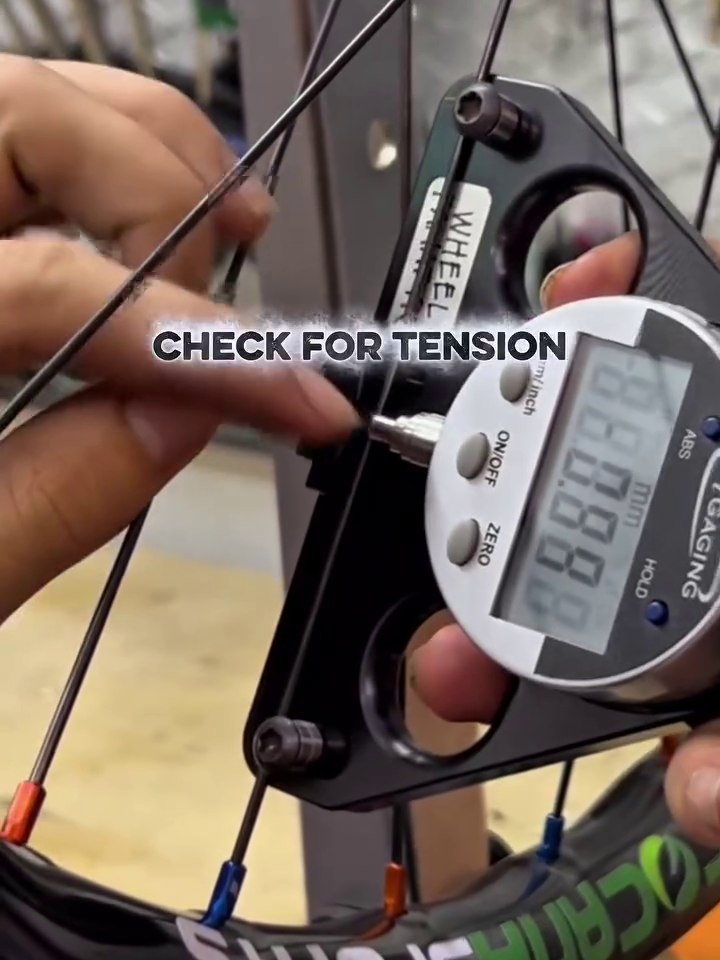

7: Check tension

Use a tension gauge.

All spokes should feel even and firm. Not too tight, not too soft.

Consistent tension = long-lasting wheels.

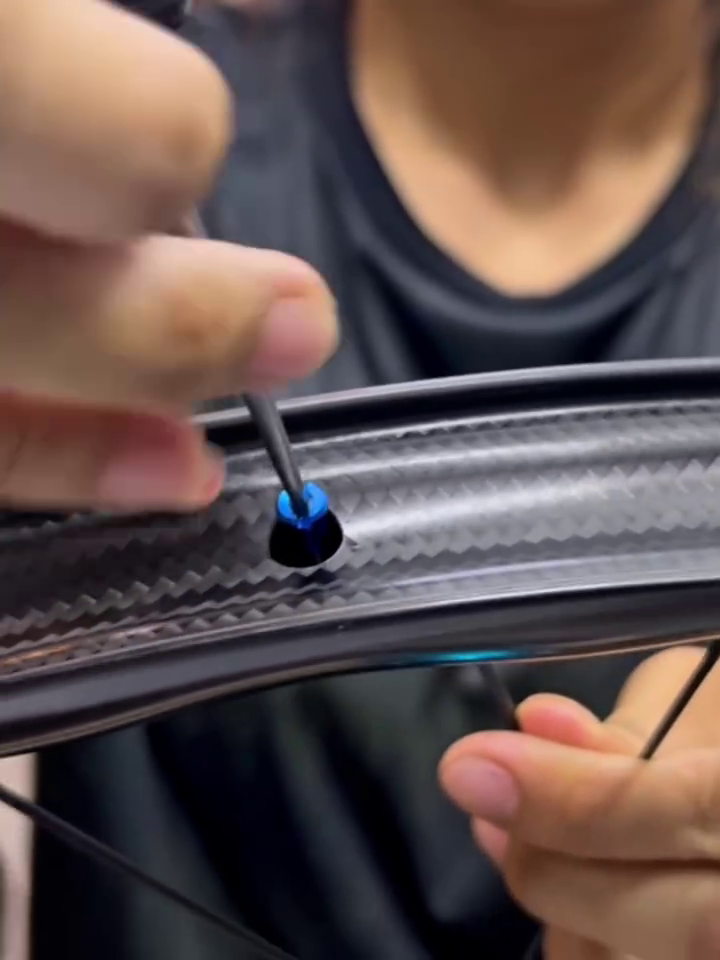

8: Apply Rim Tape

Cover the spoke holes tightly with Rim-Tape to prevent punctures.

Make sure it's centered and overlaps slightly at the end.

9: Install Tyre and Sealant

-Mount your tubeless compatible Tyre

-Add the correct amount of tubeless sealant

-Rotate and shake the wheel gently to coat the inside evenly

10: Pop the bead

Inflate the tyre until both beads pop securely into place.

Check for leaks, spin the wheel, and admire your work-

You just built a perfect, balanced, tubeless-ready wheelset!

Click for Full Video

FULL VIDEO

Wheelbuilding isn't just mechanical, it's an art of precision

Every spoke turn teaches patience, focus, and craftsmanship.

So whether you’re a first-time builder or a curious rider, try it yourself — you’ll never look at your wheels the same way again.