Product Description

Sale - Vorsprung Smashpot Coil Conversion for Fork Fox, Rockshox, Ohlins, DVOD etc

Experience phenomenal grip, control and sensitivity with the Smashpot - the bottomless fork coil spring conversion system for single crown enduro forks.

Run over EVERYTHING.

Features

- Phenomenal sensitivity & bump-eating performance

- Consistent, predictable spring rate in all conditions

- Cuts fork friction roughly in half compared to an air fork

- Adjustable hydraulic bottom out control for the big hits

- Caters to rider weights from 45kg (100lbs) to 125kg (275lbs) with 10 coil spring rates

- Allows lighter riders to get the most use out of their forks

- Allows heavier riders the support they need without the harshness that comes with excessive air pressures

- Only coil conversion system on the market allowing up to 180mm travel (fork max travel permitting)

- Easily adjust your travel with internal spacers - no new parts required

- Unique Hydraulic Bottom-out System prevents harsh bottoming

- Can be transferred between different forks with minimal parts /cost

- Reliable and low maintenance, set and forget.

- Easy to install and easily serviceable

- Please mention it's for: Rockshox Lyrik/Yari, Rockshox Pike (Non-Boost), Rockshox Pike/Revelation (Boost), Fox 36/Marzocchi Z1, Fox 38, Rockshox Zeb/Domain, DVO Onyx SC, Ohlins DXF 36 m.2, Ohlins RXF 38

- Please mention spring rate: 30lbs/in, 35lbs/in, 40lbs/in, 45lbs/in, 50lbs/in, 55lbs/in, 60lbs/in, 65lbs/in, 70lbs/in, 75lbs/in

Why Coil?

Air springs have improved substantially over the years - and we've been at the forefront of air spring development for years, so we've got no bridges to sell you.

Yeah, coils are heavier than air, and for some riders that alone is a dealbreaker - fair enough. The advantages of coil springs, however, are clear:

Zero stiction or friction in a coil spring. And no moving seals in the spring system to wear out, cause friction or leak.

Zero spring rate variation allowing more mid-stroke support and consistency.

More oil in the fork - lubrication and service life are improved.

In short, improvements in sensitivity, grip, compliance, mid-stroke support and consistency, with reductions in harshness and hand pain.

BOTTOM OUT RESISTANCE

Adjustable Hydraulic Bottom Out Control

Low weight aside, air springs outperform coil springs in one critical area: bottoming resistance. The hydraulic bottoming control valve addresses this with a speed sensitive shimmed valve which engages progressively and seamlessly in the last 50mm of travel, bringing the fork to a smooth and controlled stop at the end of the travel. High energy and low energy inputs are effectively managed without harshness. Easy tool-free external adjustment ensures you get as much or as little bottoming resistance as you need at the turn of a dial. Increased stability as energy is dissipated, rather than stored and thrown back at you.

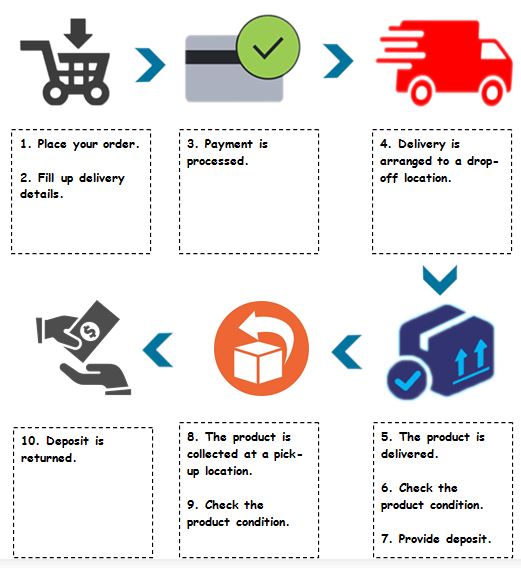

Delivery for Product Rent

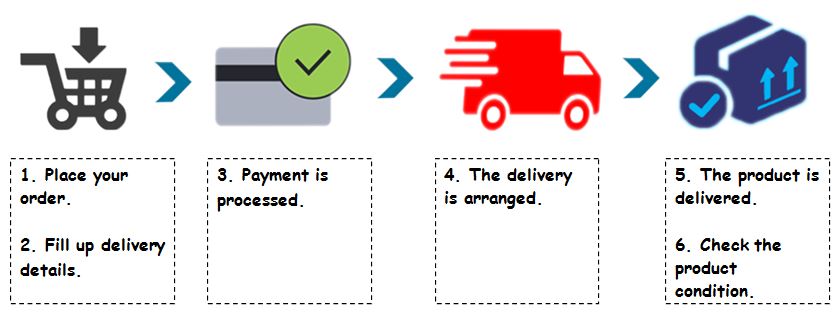

Delivery for Product Purchase

When order is placed, you will receive a confirmation e-mail.

We will contact you to proceed on the payment method & discuss about the delivery time and date.

If you have sudden change of delivery date / location, please contact us within 24 hours in advance and let us know your new delivery date / location. Extra delivery charges might apply.

Once you received your wheelies, please check its condition on the spot. Any wheelie related info, our person-in-charge is glad to provide explanation.

-1000x1000.jpg)

-150x150.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)